Melting the Manufacturing Glacier

Manufacturing is the glacier of industry.  Because production is such a behemoth of material, process, scale, regulation, safety, establishment, and bureaucracy, any changes or innovation in the business of “making things†is slow to come. However, in the last decade, we’ve seen massive shifts in the way this industry does business. Â

Slowly, the manufacturing sector is beginning to catch up to the on-time demands of customers who are used to point-and-click sale, payment, and shipping. A growing movement toward product customization, small quantity runs at competitive pricing, all with a new standard for precision and accuracy with increased automation is giving smaller, more modest manufacturing companies an edge over the big players.

Those same small makers are driving evolution industry-wide. The writing’s on the wall–the fundamentals of modern manufacturing have evolved.  Here’s a snapshot of some of the changes that are pushing manufacturing into new technologies and customer service frontiers.

The Way Things Were

It used to be that getting a part or product manufactured meant long lead times, colossal quantity requirements, and a lot of trial and error to machine parts that are accurate to customer specifications for optimal fit and function. Â

A typical production job lasted for weeks or months, which would, in turn, cause bottlenecks and sometimes even complete breakdowns in the supply chain.

Taking completed products to market depended on endless spec collection, as well as repetitive back-and-forth dialog between customers, part designers, assembly line supervisors, and shop floor workers. Each piece of cutting equipment required a skilled worker for operation.

A New Technological Movement

With the advent of CNC manufacturing, website ordering systems, streamlined shipping, and more efficient communication protocol, smaller, more agile manufacturing companies like United Scientific are making names for themselves. The days of large-quantity minimum orders and “hair-on-fire†expediting nightmares are almost over.

How is CNC Technology Helping Speed Things Up?

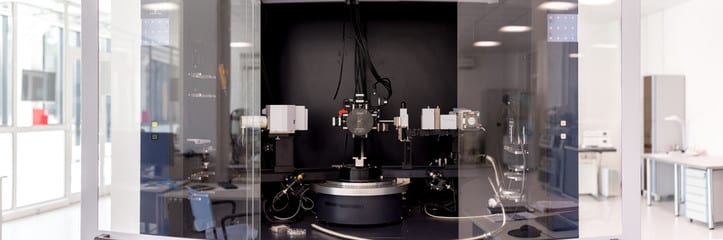

Computer Numerical Control or CNC manufacturing is the messenger of production that can respond in real time to customer needs. CNC is a machining process that uses pre-programmed computer software as well as customized coding and memory storage to cut parts that offer a higher standard of precision fit. Â

Further, because of the automation and digital aspect of CNC, near-perfect parts can be made every time with a significantly lower error rate than that of human-controlled machines. Â

Unlike in previous decades where machinists did the cutting by “hand†with several implements, in CNC manufacturing, humans do most of the work on the “prep and design†end of the part or product. Â

A design team or individual takes the specs of the desired product and feeds them into a CAD (design software) program. Once the design meets with customer approval, the part-maker then feeds the CAD design into a CAM program. CAM programs generate the “G-code†needed to tell the equipment (lathes, grinders,  or mills, for example) how to fabricate the piece.

G-code is specific in its communication with cutting equipment, providing instructions that detail the place and pace of each cut, coordinate multiple cuts on a part, and determine the feed rate of the product material through the whole process.

Once the cutting equipment has all the instructions, a product or part can be machined with a few clicks of a button, and repeated at the same precision standard for any product quantity. Also, instead of requiring a skilled worker for each cut with every piece of equipment, one worker can now “tell†several machines when and how to do the job, with a much lower margin of error.

Changes in Manufacturing Skills

The manufacturing workforce is undergoing a shift in current times. Shop floor workers must now be skilled in software operation more than the traditional machining skill sets. Machinists continue to be in high demand in the manufacturing sector. However, the new skill sets include familiarity and competence with both CAD am CAM software as it pertains to mills, lathes, grinders, and other part-making equipment. Â

Real-Time Fulfillment

Just as we’ve all seen demand for online retail product ordering and free or reduced shipping skyrocket in the last decade, we are now noticing the same trend in manufacturing. Customers want their parts, and they want them delivered with both haste and precision. Â

Also, huge quantity minimum orders are becoming a thing of the past as small manufacturers (like United Scientific) become experts at anticipating and delivering on the needs of their clients by adopting advanced technology like CNC programming, software, and equipment. Better technology means companies that build things can streamline their staff and efficiently use raw materials.  The result is a product that is both “lean†and “green†and ready for speedy delivery.

A Connected Company is a Successful One

Another aspect of the changing world of manufacturing is connectivity and communication. Customers expect to have updates and “tracking†ability in not only order shipment, but also in the whole process from design to completion. Â

If our customers can access the exact progress of the part they need for their finished product, they can better plan for their growth, their future product innovation, and the satisfaction of their end users. United Scientific is with you every step of the way as we build the part you need, cut to the highest precision standards, delivered on your timeline.

Safety and Integrity

With the ethically minded consumer now ever more at the forefront, rest assured that United Scientific has always placed a priority on the safety of our staff and the ethics of our sales and partnerships. Even though our manufacturing uses state of the art technology, our people make our company tick.

When our people are happy, it shows in our work ethic, our communication with our clients, our overall customer service, and your end product. Â

We are proud of our high ISO 9001 Certification Audit score, and ultimately, it’s our team that got us there. We are here to serve you with efficiency, accuracy, and relationship. That’s why at United Scientific, we are “scientific in process and united in purpose.â€